Polylactic Acid

What is PLA?

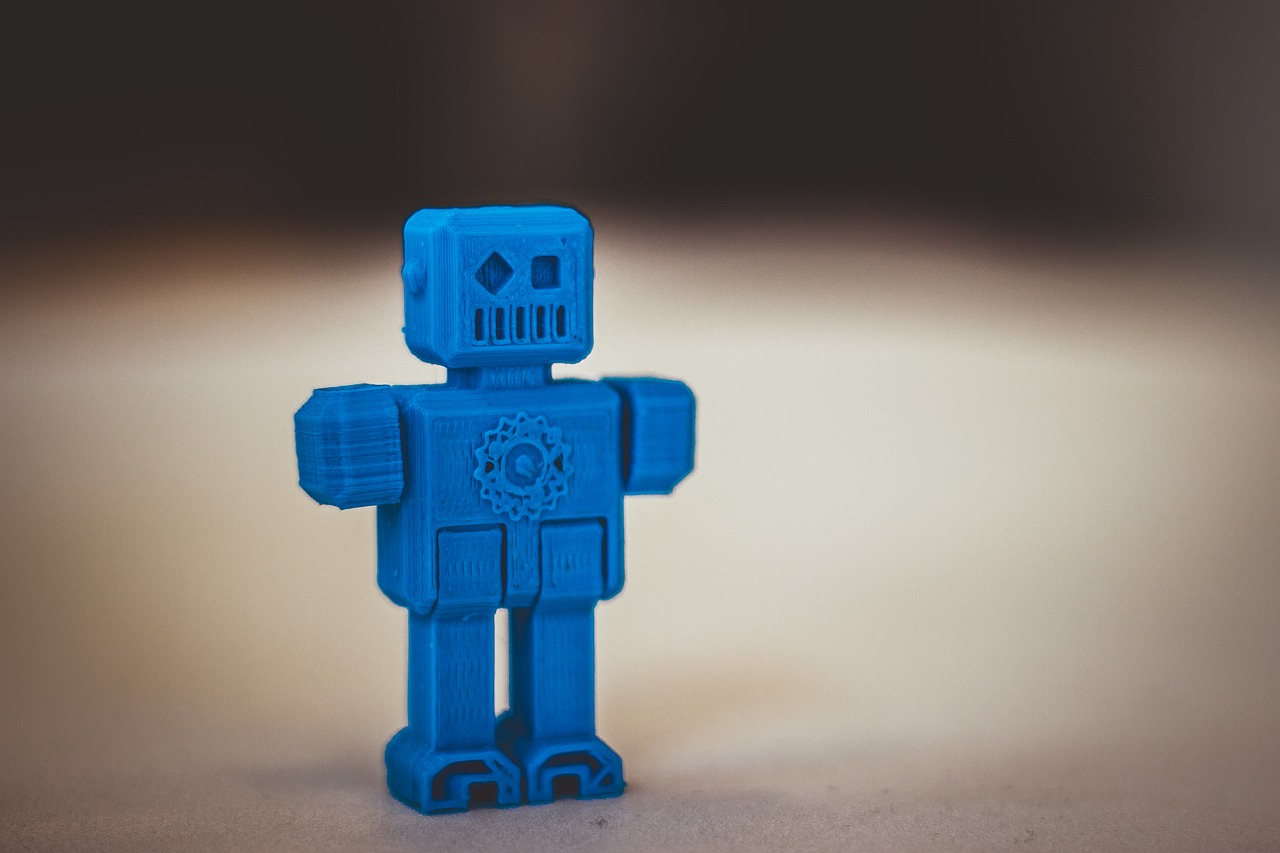

Recently, I have volunteered to 3D print parts for my robotics team. It started as a part or two, but now, the club relies on me for their 3D printing needs. After constant printing, I became curious, I use my printer every day, but I don’t actually know much about it. So, as an aspiring material scientist, I decided to research the materials inside 3D printers and get some answers. What is that stuff in a 3D printer? What is it made of? How can I put it under such an immense amount of heat but it doesn’t burn? All these questions circulated through my head. Well, today I plan to answer them.

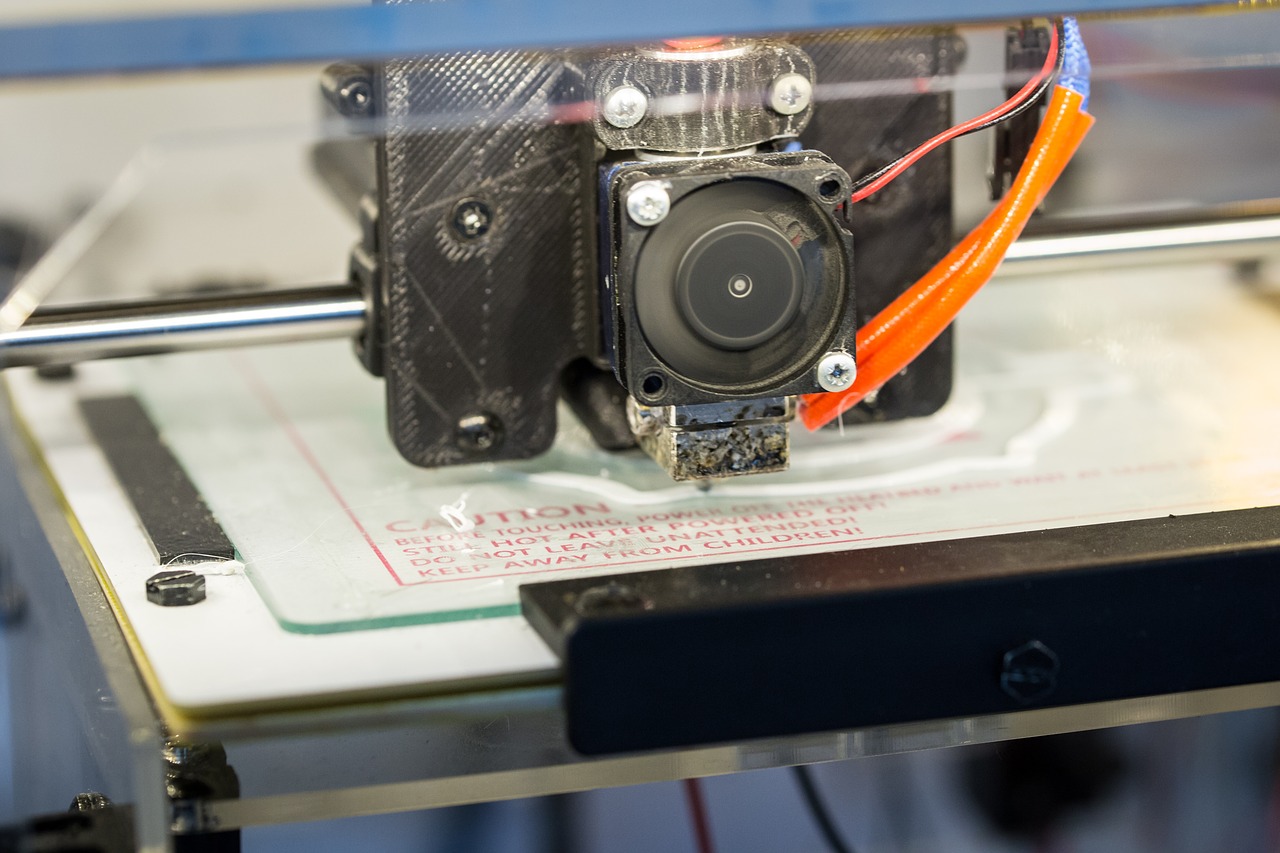

Essentially, how 3D printers work is that they draw in a filament (a plastic rod) and melt it at a very high temperature. After, they extrude very thin layers of this plastic building up to a part. There is a lot more to how a 3D printer works, but today I want to focus on the filament, specifically PLA filament.

PLA stands for polylactic acid, and to this day, PLA is the most common default filament for extrusion-based 3D printers. PLA is an inexpensive and easy-to-use filament, making it an excellent material for first-time 3D printer users. Not only is it a default filament, but it is also the most popular filament for desktop 3D printing and can produce a wide variety of parts. PLA was created by an American Chemist known as Wallace Carothers. Even though PLA was invented almost nine decades ago, it wasn’t entirely produced until the 1980s by an American company known as Cargill.

Surprisingly, PLA is biodegradable, meaning that it will not affect the environment. PLA is indeed a thermoplastic, indicating it is made of renewable materials such as cornstarch, sugar cane, and topica roots. PLA is unlike other materials, which are primarily made of other polymers such as petroleum. This gives the material the added bonus of having a sweet aroma. People have started taking PLA’s natural qualities to other uses, such as using it in food products and medical applications. And I know what you’re thinking; if PLA is made out of such natural materials, why don’t I just 3D print myself a bowl of pasta and eat it like it’s lunch. Well, although PLA is made of cornstarch, the nozzle of your 3D printer, when hot, may extrude some harmful chemicals, making it dangerous for humans to eat, so I do advise you not to consume this material.

As well, you may also be wondering how crops can be turned into solid plastic. Well, this is created by a fermentation process of a carbohydrate source. Let us use cornstarch for this example. First, the material is ground, causing the starch to separate from the corn. After the starch is mixed with acid or lactic monomers, this process creates L-lactic acid, a basic component for PLA.

L-lactic acid is also known as a non-Newtonian pseudoplastic fluid. Meaning its viscosity (flow resistance) will change depending on the stress applied to it. PLA is fine cut, causing the viscosity of the material to decrease as more pressure is applied to it.

When using PLA for 3D printing, one should know that its melting temperature is at 180 ℃, but the extruder should be around 190-220 ℃. Although a heating bed is optional, it should still be noted that the optimal temperature is from 45-60 ℃. Lastly, I would like to add that a cooling system is required and should be used at 100% power. I, personally, keep my extruder at 200 ℃ and my bed at 60 ℃.

Also, while going down my 3D printing journey, I have noticed some benefits and disadvantages to filament. Not only is PLA very cheap, but it is also strong and has good dimensional accuracy. Both are very important for creating robot parts. Where a slight measurement off can ruin a whole mechanism, some cons I noticed were PLA’s low heat resistance. If temperatures are brought too high, the filament can easily burn. Causing some very unpleasant-looking brown streaks. As well, I have noticed that PLA is brittle and can easily break. Lastly, PLA isn’t suitable in the elements, such as light exposure, and I would not recommend it for any long-term outside use.