Rubber Duckies

Rubber duckies are the bath toy we all know and love. Over the years, they have become a household necessity to help soothe every bath. However, few know the history and making of rubber duckies. In this entry, we will discuss the rubber duckies’ materials and their manufacturing process.

Rubber duckies were first created in the 1800s by a scientist, American chemist Charles Goodyear when he discovered a way to turn rubber into a malleable material. Goodyear heated the rubber with sulfur, which became moldable and waterproof when it cooled. This new form of rubber would become known as vulcanized rubber. However, rubber duckies then were not what we see now. The duckies were very solid and dense, making them not float in the water. The rubber duckies we see now, invented in the 1930s, are made of latex, allowing for their buoyant nature.

Vulcanized rubber has several outstanding advantages compared to traditional rubber. It is both stronger, allowing it to handle more stress and much more elastic. Such qualities allow Vulcanized rubber to be much more protective against abrasions and give the ability to be stressed much further without deformation. These variations in attributes give great thanks to the curling process, which heats sulfur and rubber together. This technique creates new cross-links within the rubber, giving the material its unique strength and elasticity.

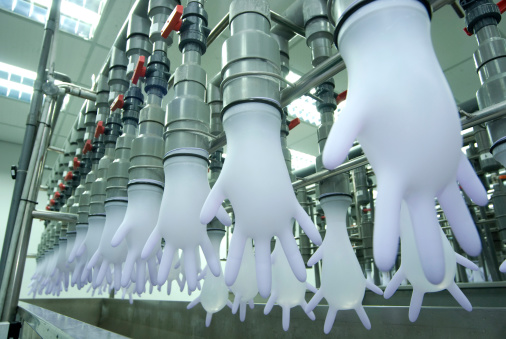

Yet, as stated previously, modern rubber duckies are made from latex. Latex is known for its impressive elongation abilities and tensile strength. Natural latex is made very similarly to vulcanized rubber. Latex sap is harvested from specific rubber trees and pre-vulcanized into rubber. However, not all latex materials are natural. Synthetic latex is made from petroleum. The petroleum-based chemicals are used to create polymer clumps. These clumps are forced through a narrow opening and placed in the mold, where they will be vulcanized and compressed. However, most products are made from natural latex. The primary use of synthetic latex is as coating or in glues and cement for their ability to solidify with the evaporation of water.

It is quite interesting to recognize the vast effects of advances in materials. It is easier to realize how much our innovation affects our lively hoods once we take a moment to view them through the lens of a small product. Everything around us is slowly growing, improving, and advancing. Every item represents years of science and innovative thinking working together to change our ways of life. I hope you enjoyed this entry and learned something new.